Step by step guide

Master: replace hose reel parts

Servicing our pressure washers are quite straight forward and could be done by most people by following the step-by-step instructions in this manual.

Please go trough the whole manual before starting work on your pressure washer to make sure you understand the procedure and that you have the necessary tools to complete the task.

Always unplug the pressure washer from both the mains power and the water outlet before starting the service.

Even though power and water is disconnected there may be pressurized water in the hose. Discharge this pressure by pulling the trigger on the gun.

Make sure your work area is clean and appropriate for the work you are about to do. There will usually be a small amount of water inside the pump and hose.

If you are doing a 10-year service, then be prepared to collect the used oil from the oil chamber. Please dispose of the oil in accordance with local law and regulations.

ISO 46 hydraulic oil can be substituted with similar non detergent oil of the same viscosity.

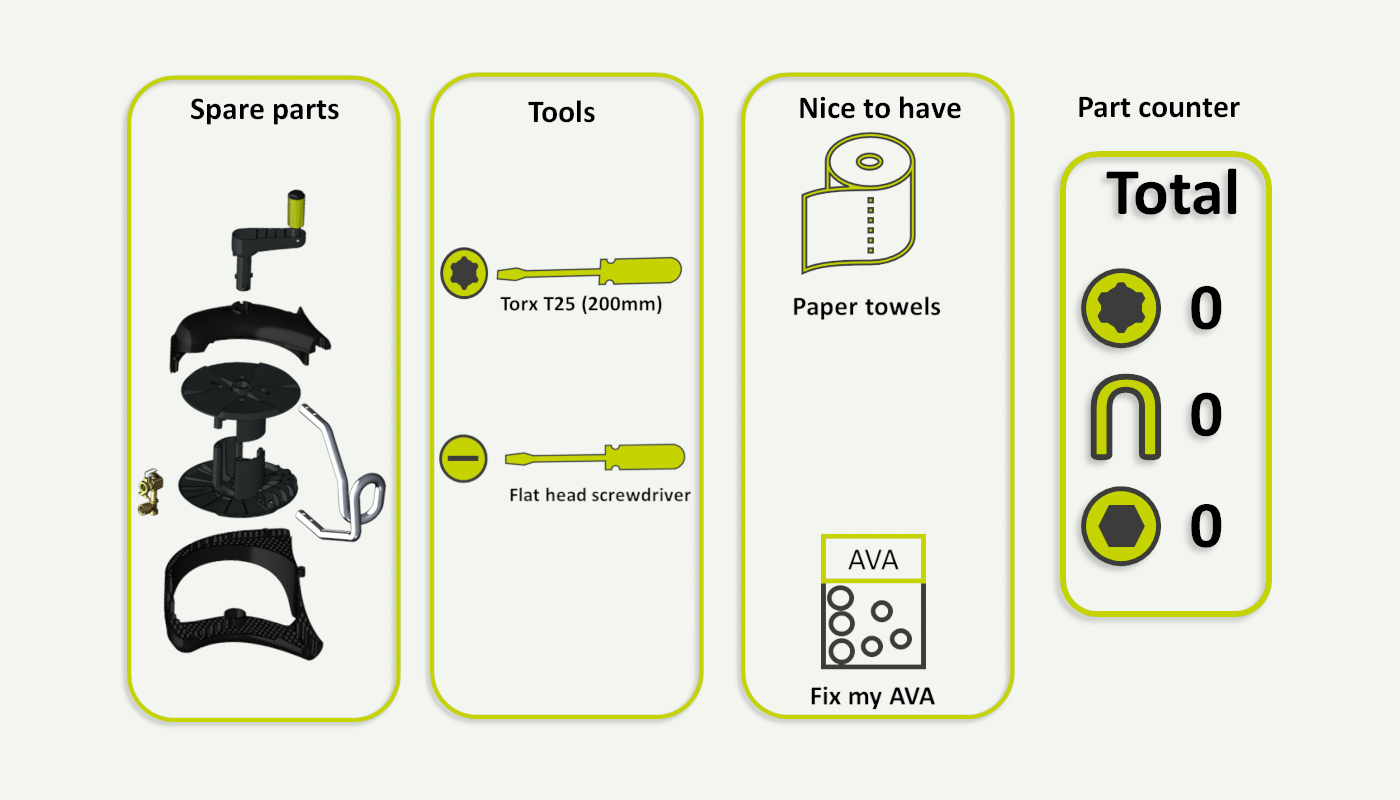

00. Parts and tools

An overview of what is needed to do this service.

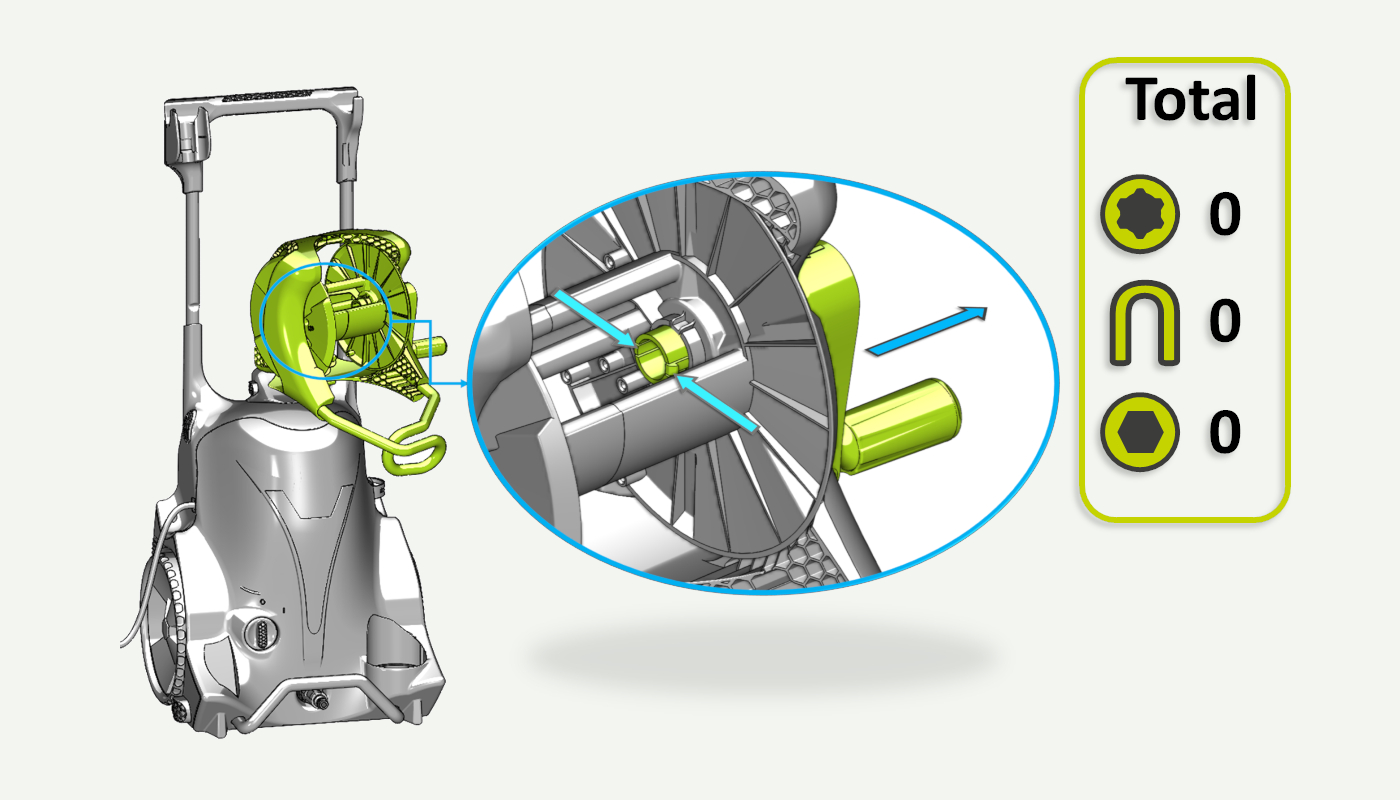

01. Remove the hose from the hose reel

Remove the hose from the hose reel.

Push in the two hooks while pulling the reel handle outwards to release the handle from the hose reel.

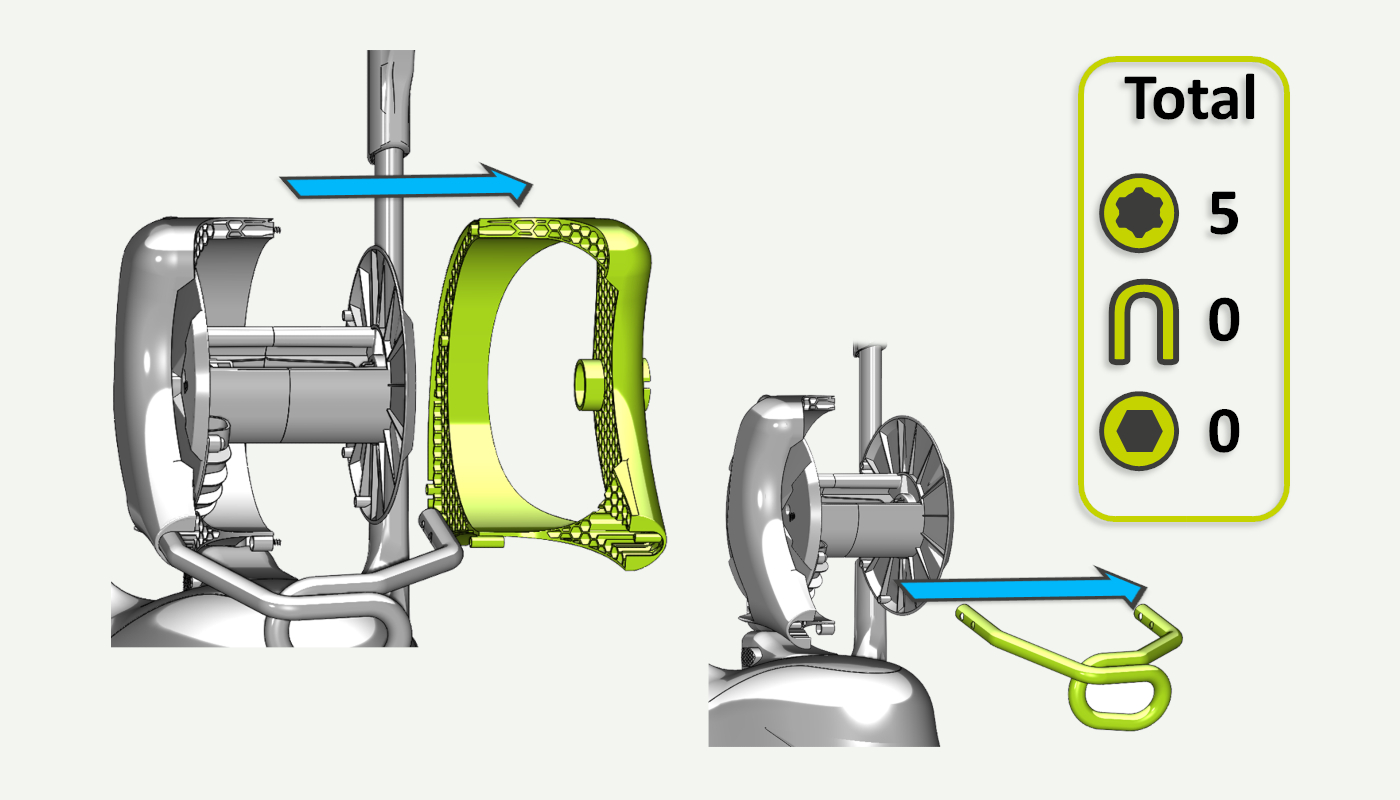

02. Remove the handle from the reel

Remove the handle from the reel.

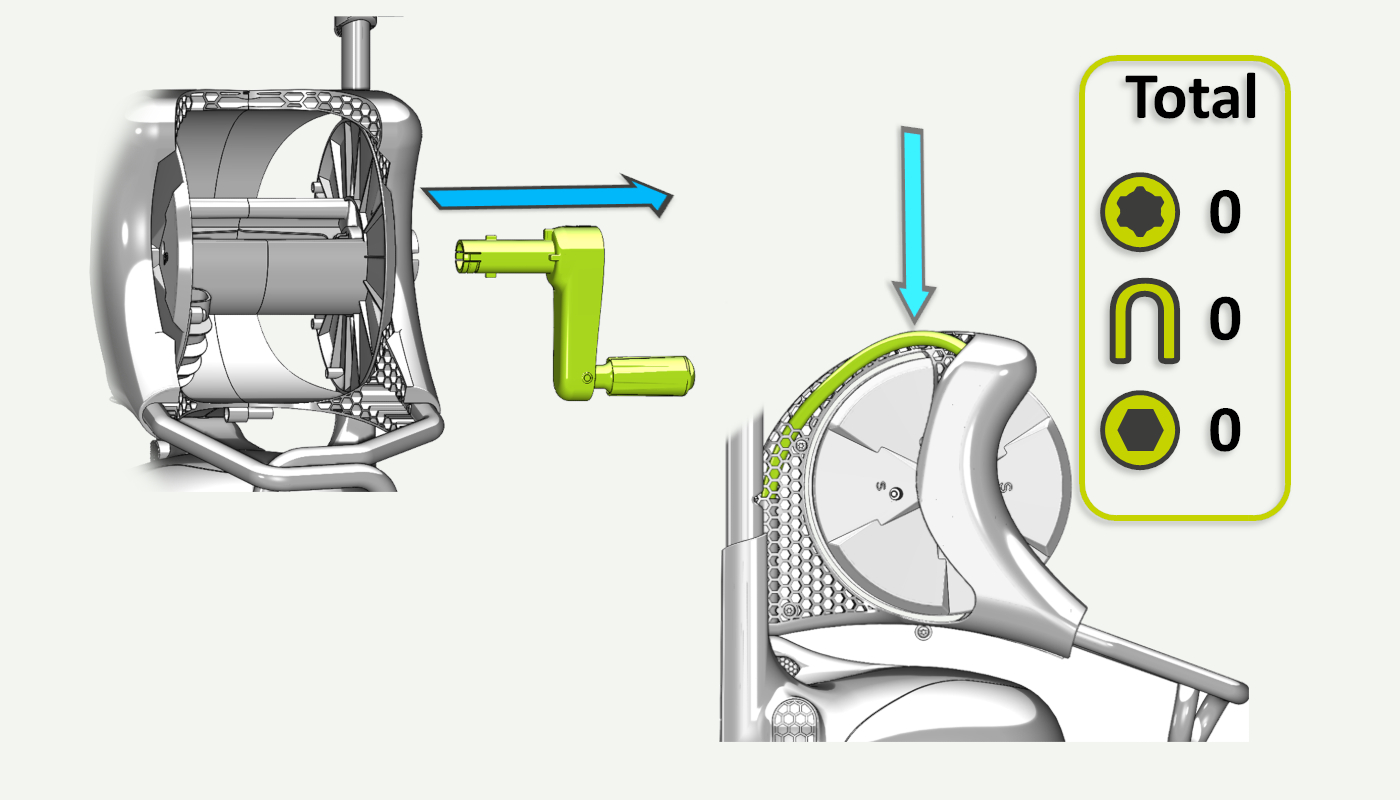

Move the hose on the reel slightly downwards to expose one of the Torx screws.

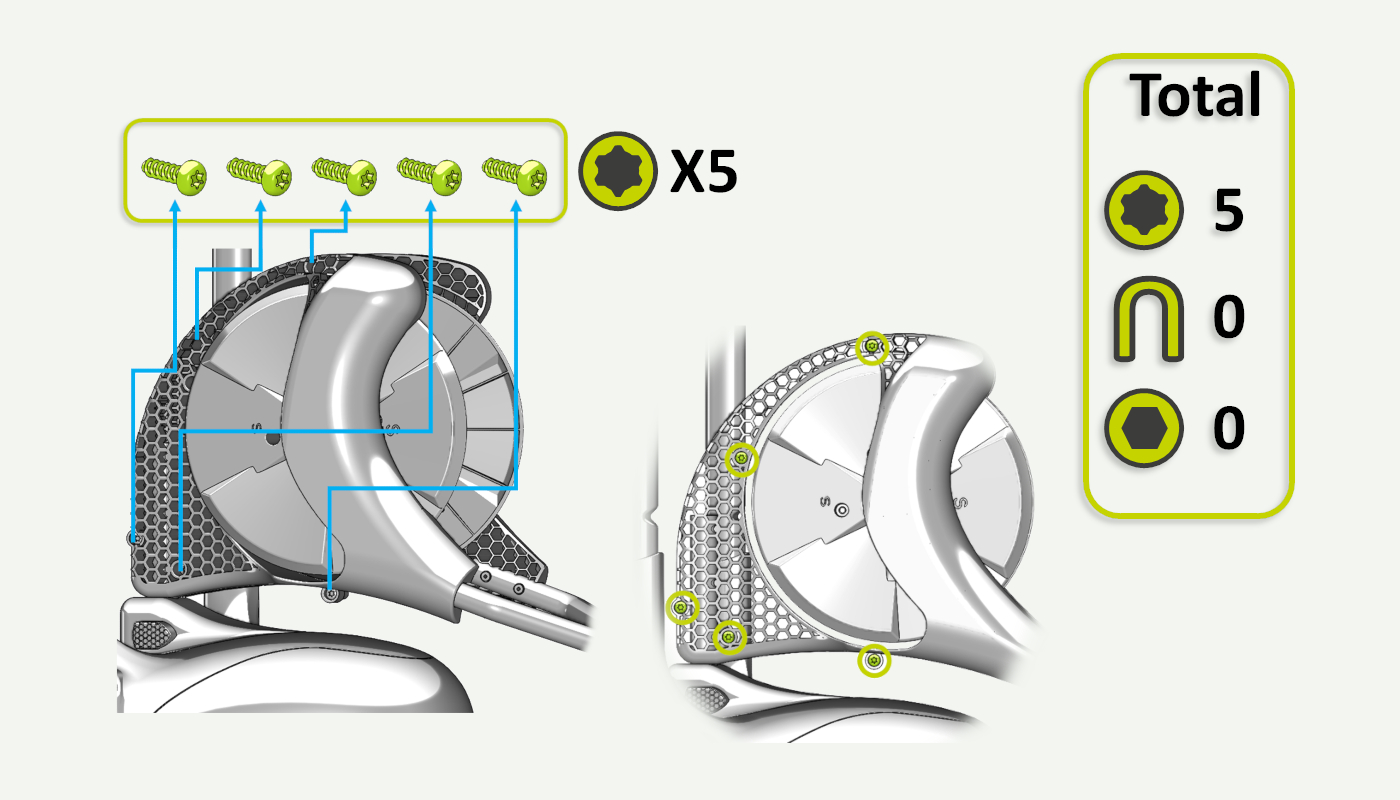

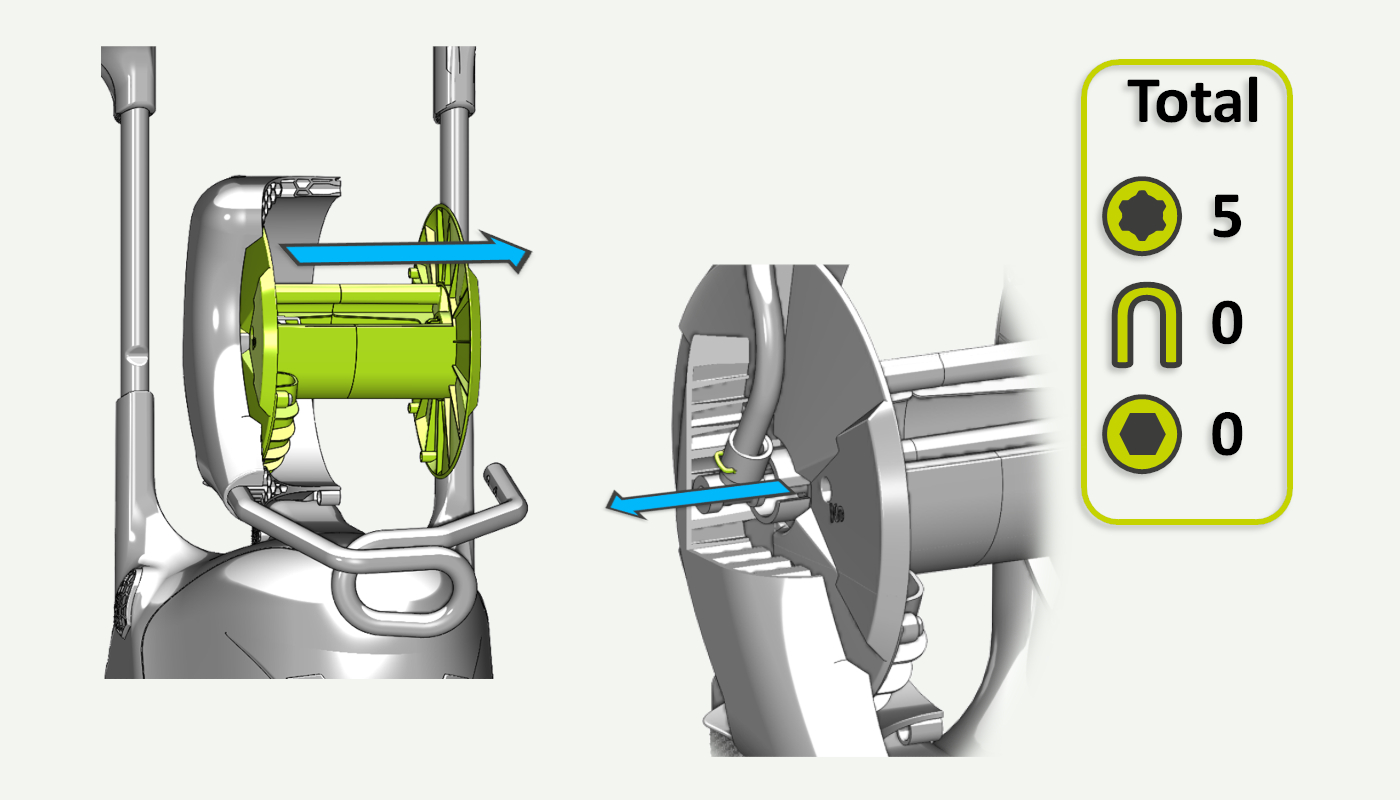

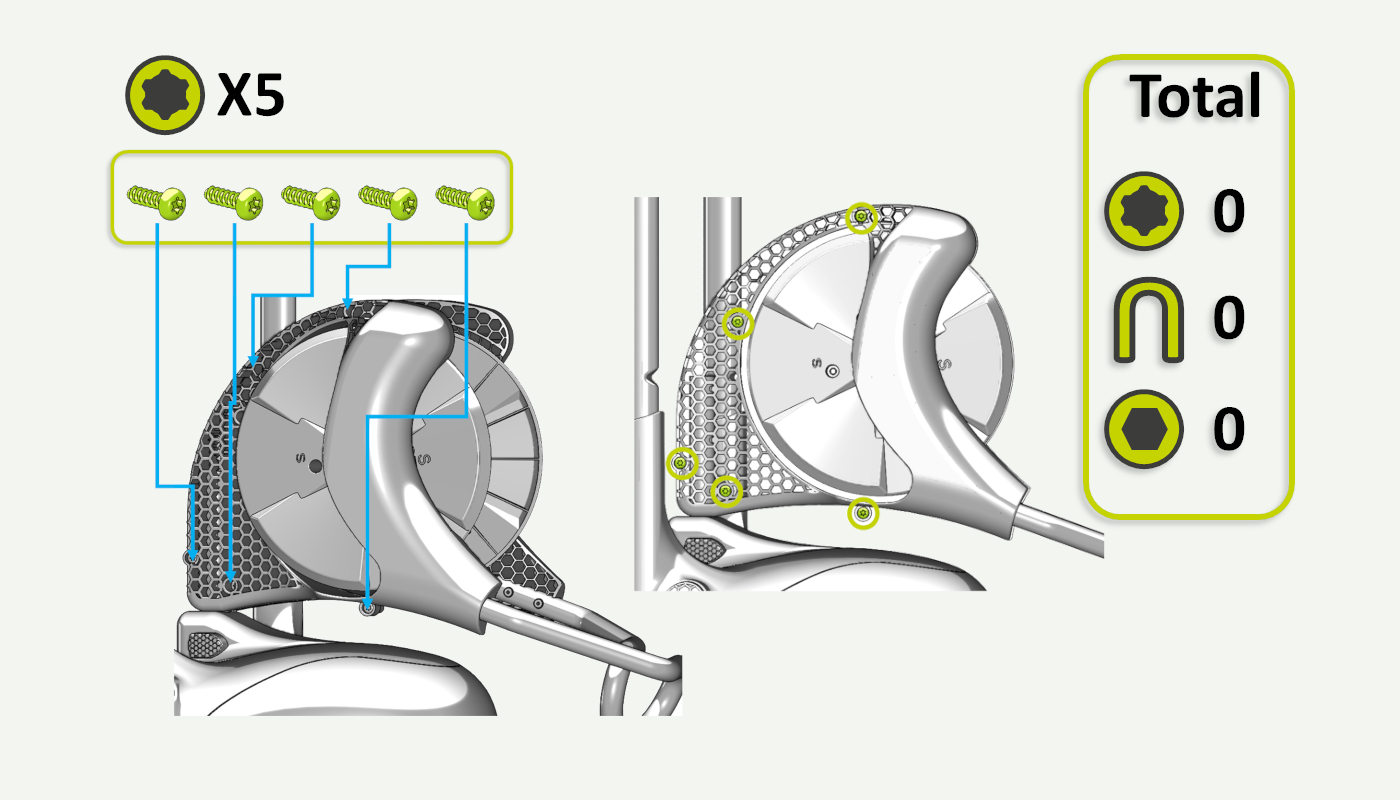

03. Remove screws from the hose reel

Remove the 5 screws on the hose reel.

04. Disassemble the hose reel

Remove the right side of the hose reel frame.

Remove the hose guide.

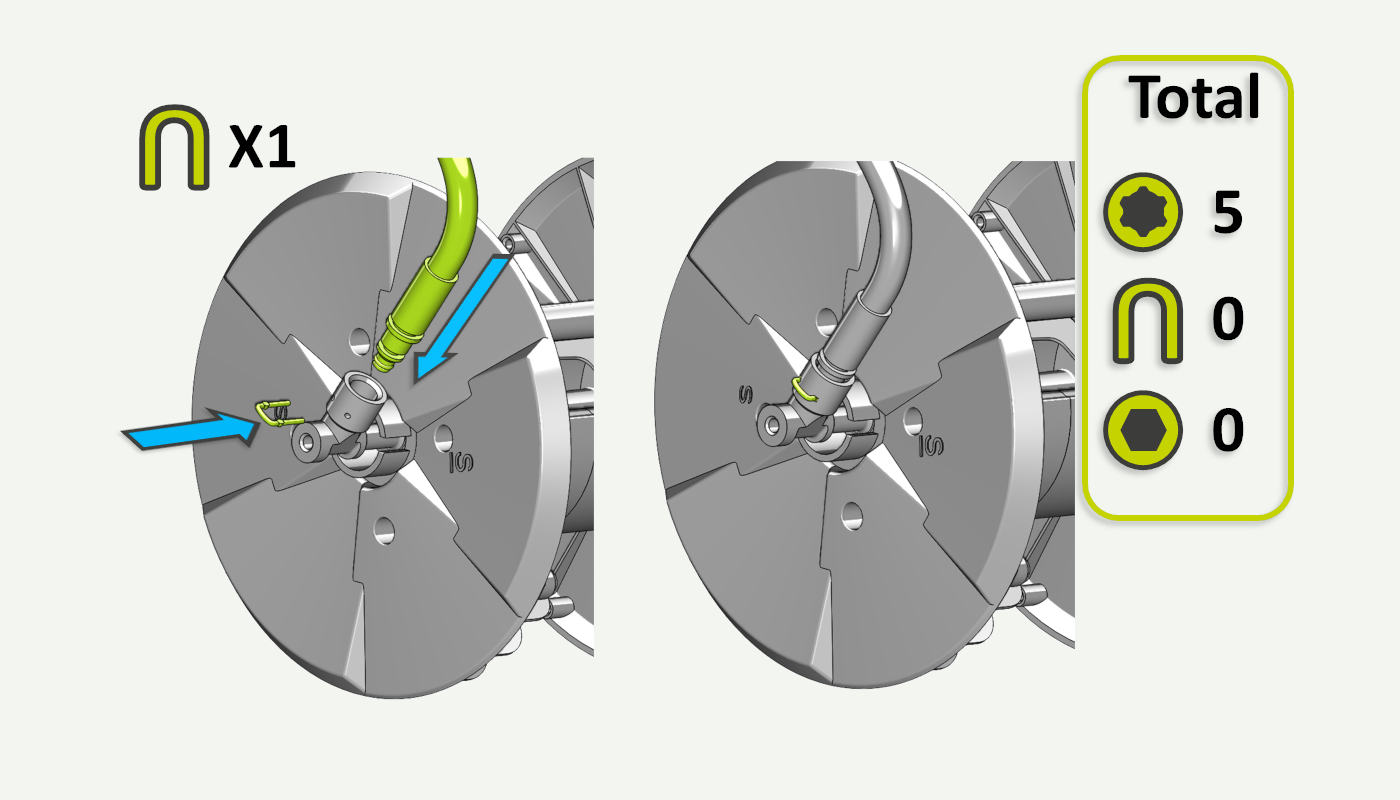

05. Remove the U-pin from the swivel

Pull the hose reel to the right to access the hose reel swivel.

Remove the U-pin securing the hose to the swivel.

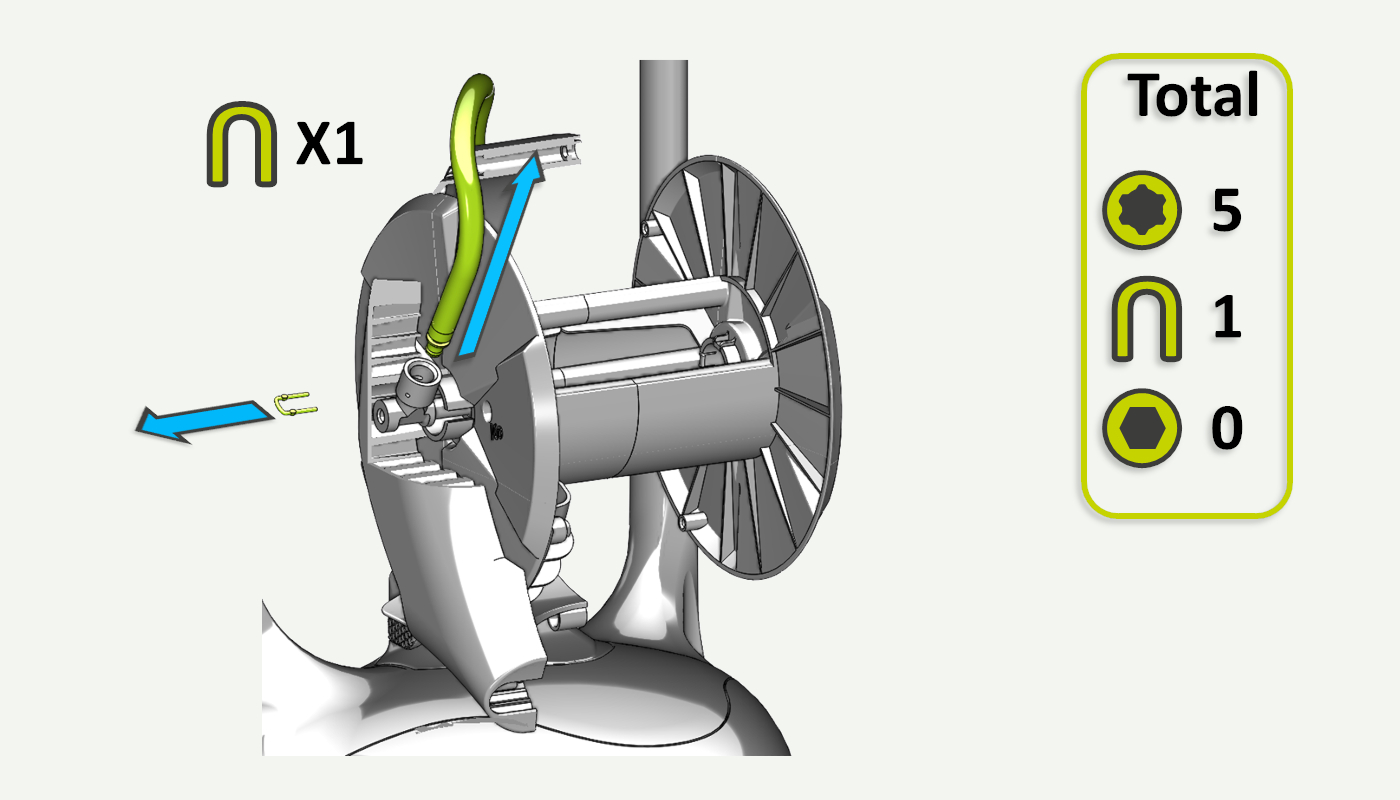

06. Remove the hose from the swivel

Pull the hose out of the swivel.

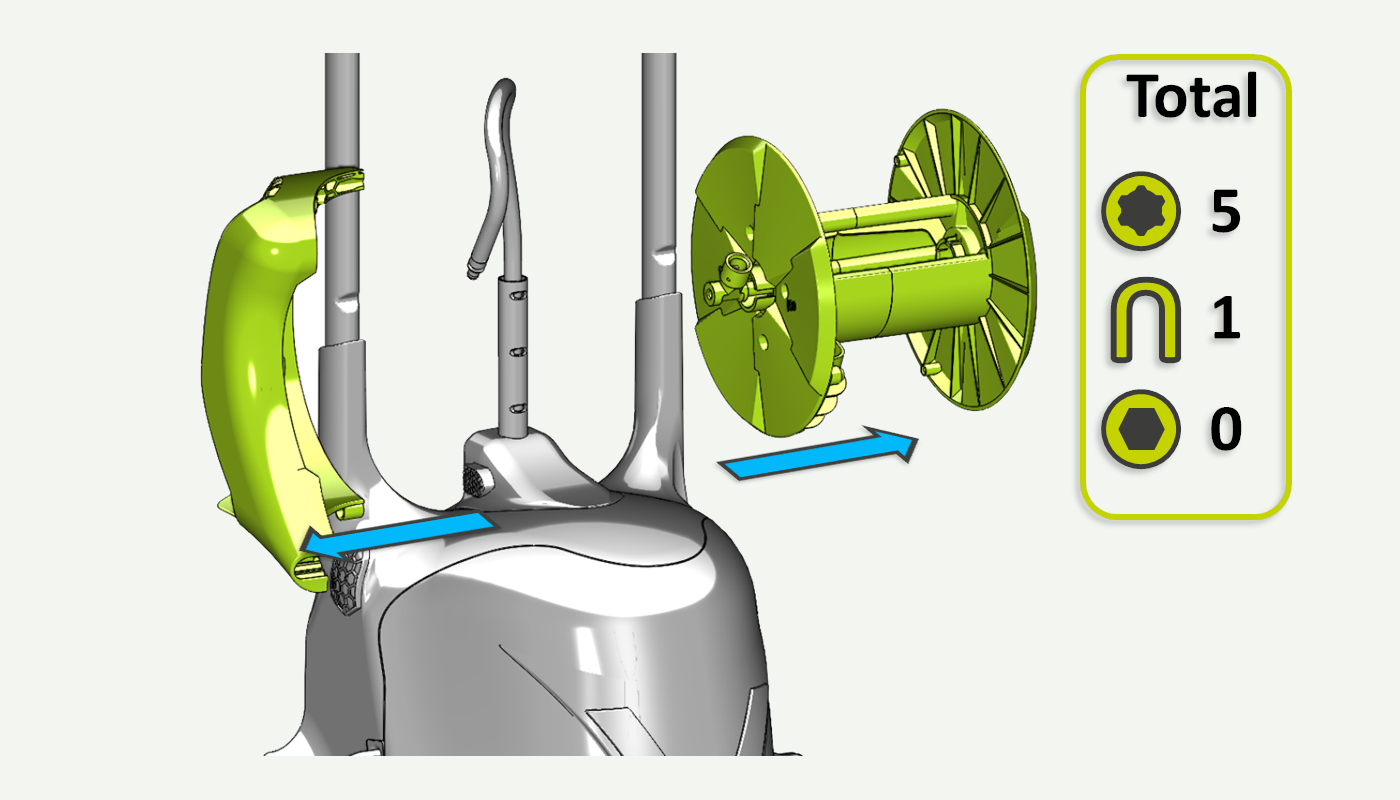

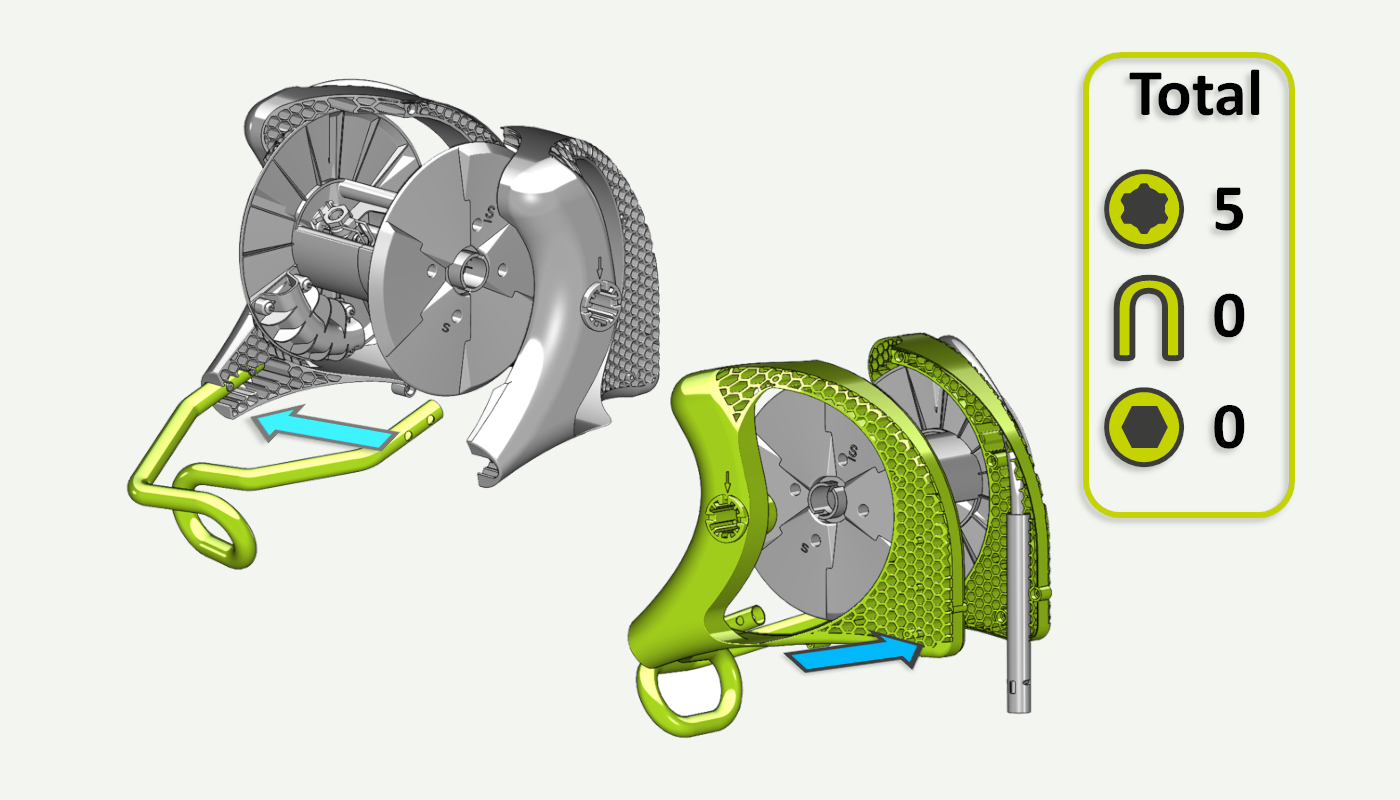

07. Remove the rest of the hose reel assembly

Remove the left reel holder and the hose reel.

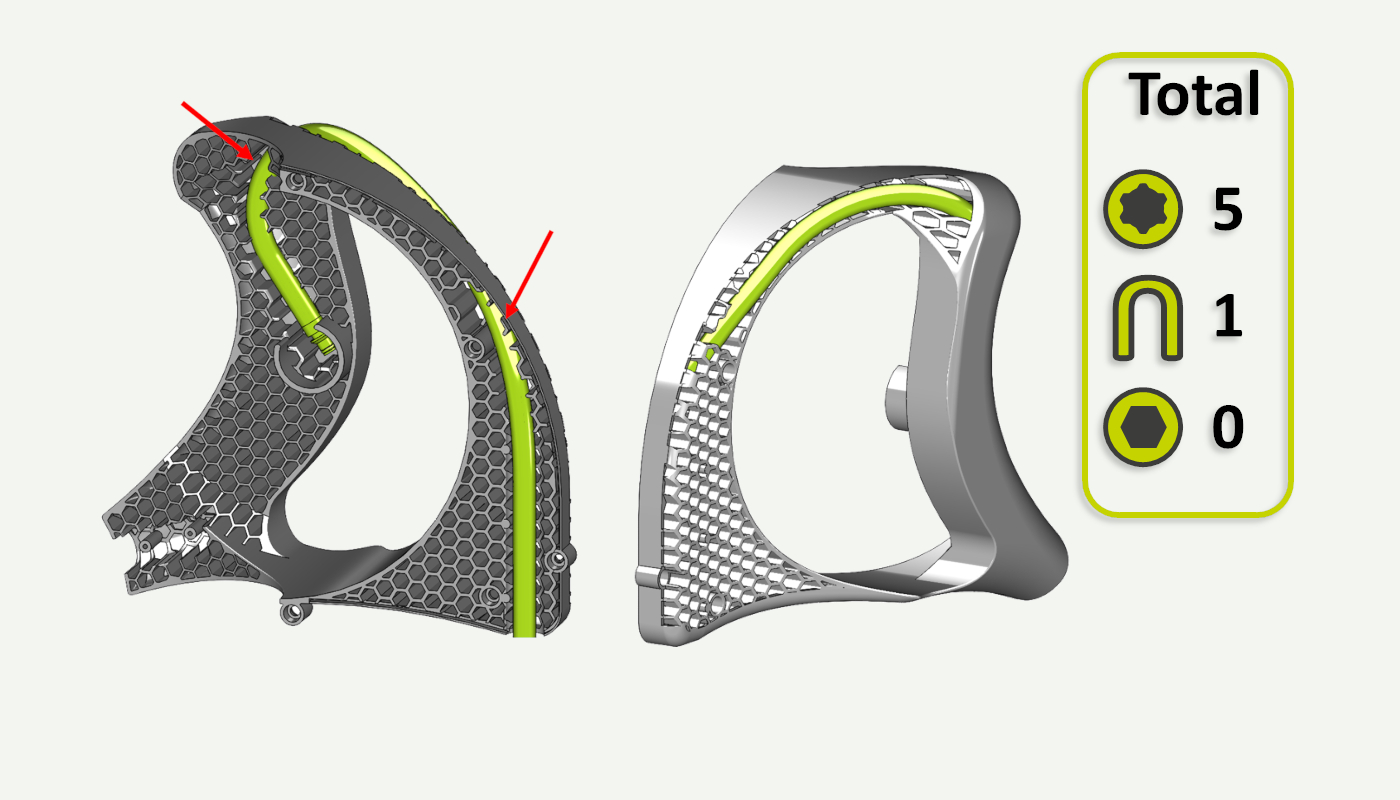

08. Fit the internal hose

Fit the hose to the left side hose reel holder as indicated in the pictures.

The end of the hose should reach approximately to the centre of the reel holder.

09. Connect the hose to the swivel

Connect the hose to the swivel in the hose reel.

Secure the hose with a U-pin.

10. Assemble the hose reel

Attach the hose guide to the left reel holder.

Put the two reel holders together over the reel tube.

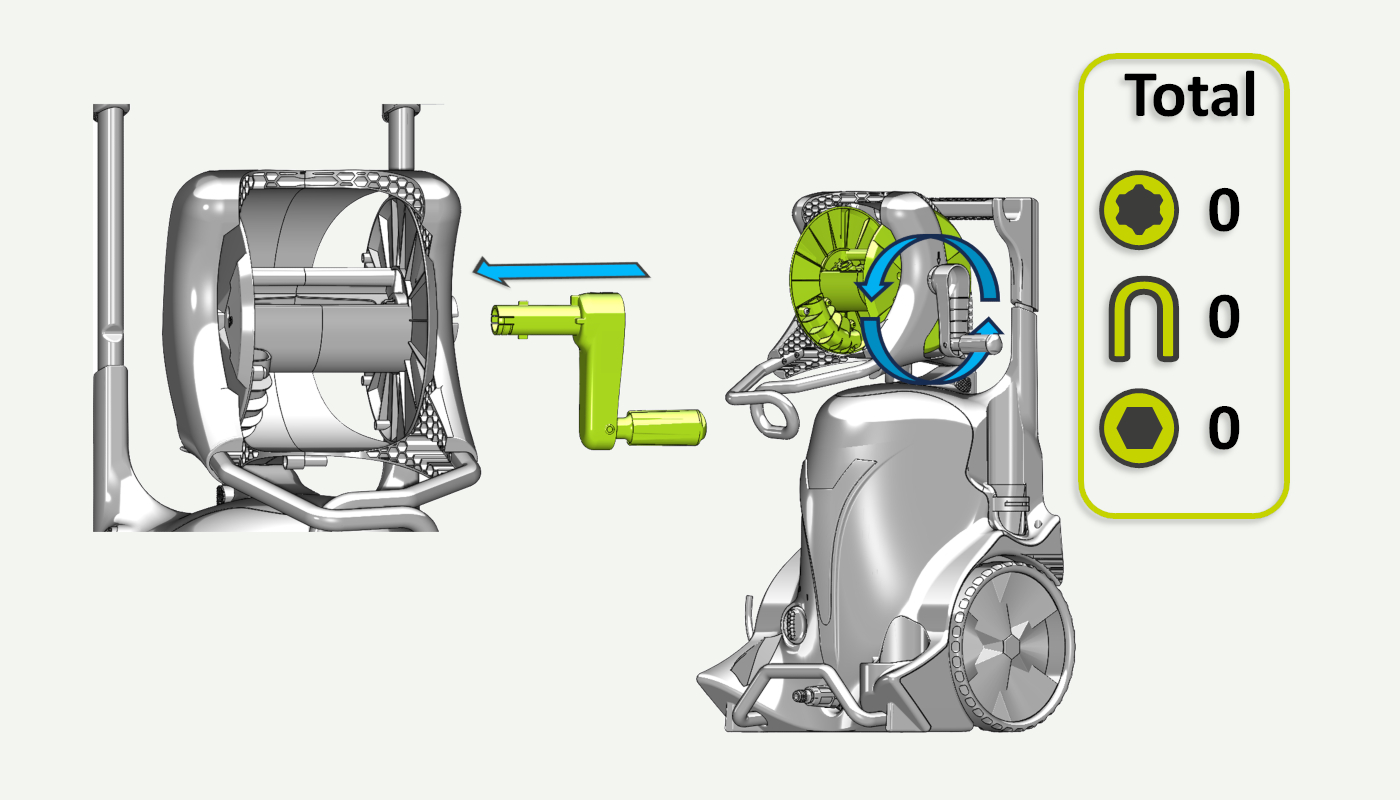

11. Securing the hose reel

Secure the left and right reel holder with 5 Torx screws.

12. Attach the handle

Reattach the handle. It should click into place.

Check that the hose reel can rotate freely. Reel in the hose.

13. First start after service

Congratulations with finishing the service of your AVA product.

It is now time to do the first start after service.

- Start by connecting the pressure gun to the hose.

- Connect water.Make sure no water is leaking from the inside or anywhere else on the pressure washer.

- Pull the trigger and let the water flow until there is no more air coming out.

- Connect the power cord.

- Turn on the pressure washer.

- Pull the trigger and let water run for a minute before connecting a nozzle.

- Connect the nozzle.

- Use the pressure washer and make sure it is operating as normal.

14. Troubleshooting

Water is leaking from the inside

- Disconnect the power and open the pressure washer to locate the leak.

- Take necessary action to remedy any leaks.

Motor runs and won't stop when you release the trigger

- This is most likely due to an improper seating of the switch box on the start/stop valve.

- Open the machine and check that the switch box is correctly seated.

The pressure washer won't turn on

- Check that the power cable is connected.

- Check that the circuit breaker has not been tripped.

- Check that the fuse in the power plug is intact (UK models only).

- Open the machine and check that all the internal cabling is connected.

Poor performance/pressure

- Improper assembly or dirt/debris in the pump.

- Check that the pump and especially the main valve for foreign objects/debris.

- Make sure that the spring in the main valve is correctly seated and working as intended.

Motor is making a humming noise and is not able to start

- Check that the capacitor is connected to the motor.

- It should be connected with one white and one black cable.