Article

Difficult to attach hose to gun?

When the hose is inserted into the gun, there is an o-ring (1) on the hose that should seal. If this is dry, it can feel difficult to remove or attach. Here, you can use almost any type of grease to make it slide better, which will also prolong the life of the o-ring, and the hose will also move more easily when you work with the gun.

In a few very rare cases, we have seen that the bend sleeve (2), i.e., the rubber lining around the end of the hose, has shifted slightly, so that it prevents the hose from reaching all the way in, or makes it difficult to lock it in place.

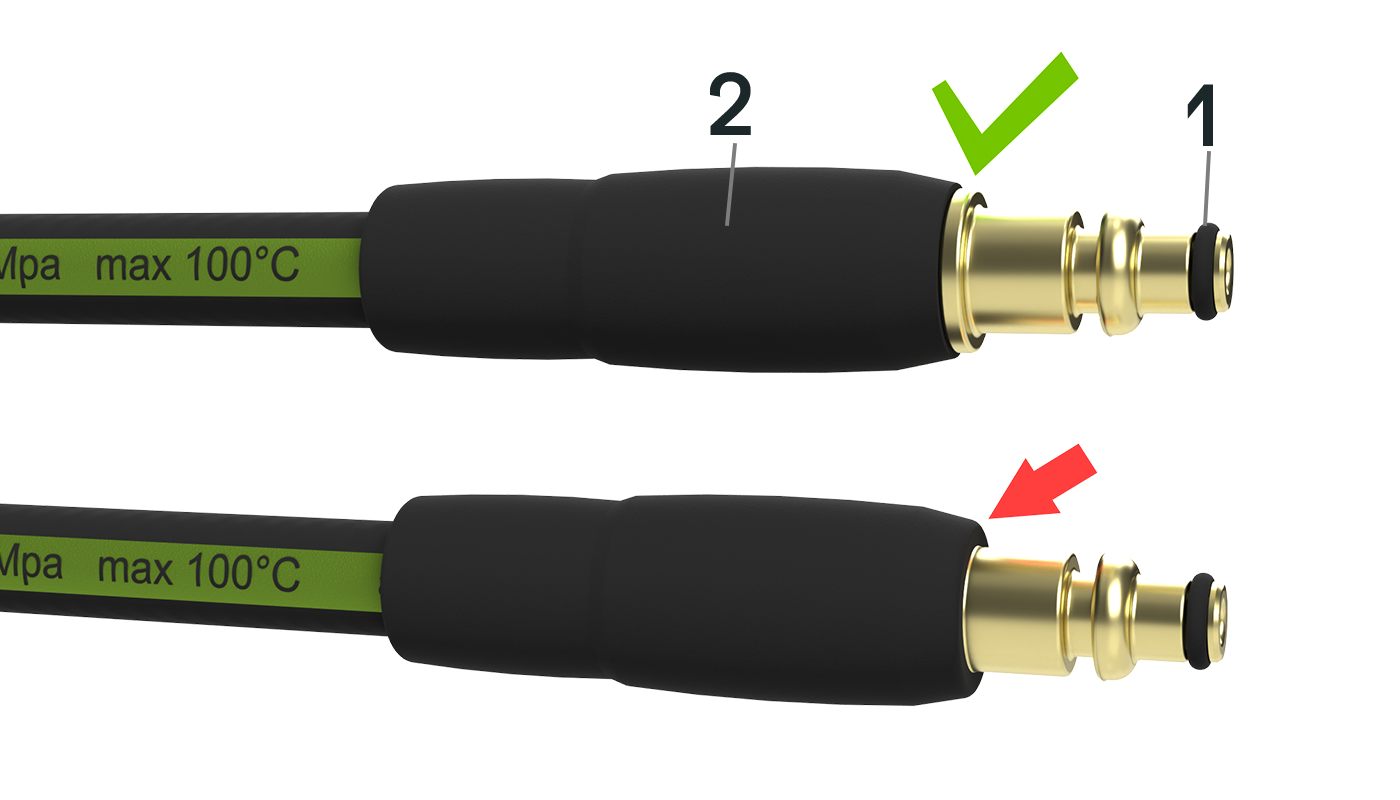

When the sleeve is positioned correctly, the rear edge of the quick coupling should be visible. This is shown in the top example below. In the bottom example, you can see that the sleeve is too far forward on the quick coupling.

If the sleeve extends beyond the edge marked with a red arrow, it can be pulled back by pulling on it slightly. An alternative is to cut away a bit with a utility knife or similar.